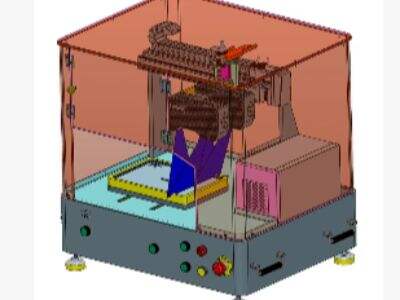

It is part of automated optical inspection (AOI) system which is essential to assuring products meet high-quality requirements. This advanced technology ensures fast and accurate acquisition of solder joint defects; guaranteeing that electronic devices work properly. So, let us take a dive into the significance of AOI in quality control and the capability of it in detecting solder joint failures with accuracy.

Knowing the important and significance of automatic optical inspection

As the process of quality control is vital to make sure that your products are serving their purposes well. AOI technology is adopted in Jakange to make sure that every electronic device manufactured is of high quality. With aoi machine systems we can fully check the solder joints of circuit-boards and no mistakes can escape our attention.

What is it about AOI’s Technology that detects solder joint defects accurately?

AOI machines utilize high-speed cameras to take extremely clear photographs of solder joints. Then these images are processed by advanced algorithms to find any anomaly or defect. A splendid Audio and Visual programming comparison system, is capable of accurate identifying the failed solder joints out of the spec by comparing the above images with the standard in advance, and it further enables us to make immediately correctitude process.

Another important advantage is the decrease in human error through use of automatic optical inspection systems.

Contrary to visual inspection, that tends to be inconsistent and error-prone, 2D AOI Inspection Equipment ensures reliable and consistent quality checks. With the inspection automated, we can take out the possibility of human error and ensure that every solder joint is inspected!

The benefits of in-situ monitoring of solder joint reliability are significant.

AOI can also provide immediate feedback for the quality of the solder joints, which gives us the opportunity to take action right away. This real time monitoring is key to catching defects early in the build process and avoiding expensive rework or recalls down the road.

To improve the efficiency and reliability in electronics industry, AOI is necessary to detect defects and keep the quality of high standard. With AOI systems, we are able to find defects fast and accurately, helping us to make any adjustments that are needed to make sure our products are the best they can be for our customers. By proactively taking these measures, we are able to streamline quality control and instill confidence in customers.

Table of Contents

- Knowing the important and significance of automatic optical inspection

- What is it about AOI’s Technology that detects solder joint defects accurately?

- Another important advantage is the decrease in human error through use of automatic optical inspection systems.

- The benefits of in-situ monitoring of solder joint reliability are significant.