Just imagine if you could measure things three different ways — length, width and height — the way you can in your MOST FAVORITE VIDEO GAMES! 3D measurement tools allow us to conceptualize the whole size and shape of an object. This technology has been used in countless jobs — from car manufacturing to home construction — to ensure that things are being made the right way.

Ever think about how builders and architects ensure that their project plans are flawless? They can generate precise computer models of their projects with 3D measuring tools. That helps them take precise measurements to ensure everything clicks together offline. It also can save time and money by catching errors before they turn into major headaches.

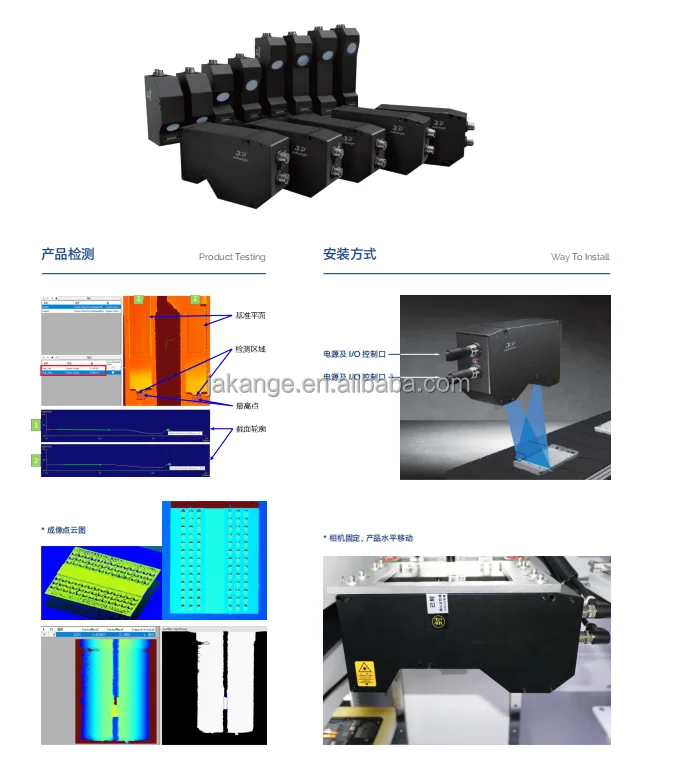

3D measuring instruments can be small enough to hold in your hand, or large machines capable of scanning an entire building. The tools rely on lasers or cameras to take highly detailed, often 3D, measurements of objects. They build digital models that can assist in analysis and visualization. Some of them even come with software that can compare these measurements to industry standards, making it easier to maintain quality.

New 3D measuring instruments are upending many jobs around the world. For instance, in automobile manufacturing they help ensure that every car part is made right, which makes cars safer and better. In medicine, 3D measuring tools are used to design prosthetics and implants that are custom made and fit precisely, making it possible for patients to live better lives.

The quality in producing products should be good enough to make them usable and safe. The newest 3D-measuring tools let companies inspect parts for problems quickly. That allows them to correct any problems before they ship products to customers, which can save time and money.