Կարող եք մտածել, որ արդյունաբերական մեքենայական տեսողության համակարգերը գերխելացի ռոբոտներ են, որոնք օգնում են գործարաններին ստուգել բոլոր իրենց արտադրանքների որակը: Այս բարձր տեխնոլոգիական մեքենաները տեսնում և հասկանում են, թե ինչ է կատարվում գործարանում՝ օգտագործելով լուսանկարչական սարքեր և համակարգիչներ: Նրանք արտադրանքները դարձնում են ավելի լավ՝ աշխատանքներ կատարելով ավելի արագ և հարթ, ինչպես նաև պահպանում են մարդկանց անվտանգությունը աշխատանքի ընթացքում:

Մեքենայական տեսողության համակարգերը զգալիորեն էվոլյուցիա են կրել ստեղծման օրվանից։ Նախկինում դրանք մեծ ու ծանրաշարժ էին և հնարավորություն ունեին միայն հիմնական գործառույթներ կատարելու։ Սակայն նոր տեխնոլոգիաների և համակուրճային ուժի շնորհիվ այժմ դրանք կարող են կատարել հրաշքներ, ինչպիսիք են ձևերի, գույների մշակումը և նույնիսկ թվերի ու տառերի ընթերցումը։ Դա դրանք դարձնում է հզոր օգտակար բազմաթիվ արդյունաբերություններում՝ սկսած ավտոմեքենաներից մինչև սննդի փաթեթավորում։

Որակի վերահսկողությունը կարևոր դեր է խաղում արտադրության ընթացքում՝ ապահովելով, որ ամեն ինչ ճիշտ լինի մինչև ապրանքների ուղարկումը սպառողներին: Գործարանները հիմա կարող են ստուգել արտադրանքները արդյունաբերական մեքենայական տեսողության համակարգեր արագ և ճշգրիտ՝ հայտնաբերելով ցանկացած սխալ կամ թերություն, մինչև այն նկատելը հնարավոր լինի մարդու աչքի համար, ինչը օգնում է ընկերություններին խնայել ժամանակ և գումար՝ հասցնելով խնդիրները վաղ փուլում և համոզվելով, որ թողարկվող ապրանքները լինեն լավագույնները:

Արդյունաբերական ձեռնարկությունների աշխարհում ժամանակը կարևորագույնն է: Արդյունաբերական մեքենայական տեսողության համակարգերը, որոնք կարող են կատարել այն ամենը, ինչ նախկինում կատարվում էր ձեռքով, կարող են օգնել արտադրամասերին ավելի արագ և արդյունավետ աշխատել: Նրանք նաև կարող են վերահսկել պաշարները, ստուգել սարքավորումները ցանկացած խնդրի համար և օգնել ռոբոտներին համագործակցել: Սա նվազեցնում է աշխատանքային ծախսերը և խնայում է ժամանակ, ինչը նշանակում է, որ աշխատակիցները կարող են կենտրոնանալ ավելի կարևոր պարտականությունների վրա:

Արտադրության գործում անվտանգությունը հիմնական դեր է խաղում: Գործարաններում օգտագործվող մեքենայական տեսողության համակարգերը կարող են նաև օգնել աշխատողների անվտանգությունն ապահովել, հսկելով սարքավորումները՝ ցանկացած խափանման նշանների համար և զգուշացնելով խնդիրների դեպքում: Նրանք նաև կարող են կանխել վթարներ, ապահովելով, որ սարքավորումները ճիշտ են աշխատում և պահպանվում են անվտանգության կանոնները: Սա աշխատողներին տալիս է հոգու խաղաղություն, որպեսզի նրանք կենտրոնանան իրենց աշխատանքի վրա, այլ ոչ թե վնասվածք ստանալու վախի վրա:

Ինչպես տեխնոլոգիան առաջընթանում է, այնպես էլ արդյունաբերական մեքենայական տեսողության համակարգերը առաջընթանում են: Այս ոլորտում նոր մի ուղղություն արհեստական ինտելեկտի և խորը ուսուցման ալգորիթմների կիրառումն է՝ մեքենաներին ավելի խելացի դարձնելու համար: Այդպիսով, դրանք այժմ կարող են սովորել և հարմարվել նոր միջավայրերում՝ ավելի արդյունավետ դառնալու համար: Մեկ այլ հայտնի ուղղություն 3D տեսողության համակարգերի աճն է, որոնք մեքենաներին թույլ են տալիս տեսնել և հասկանալ օբյեկտները եռաչափ տարածության մեջ և ստեղծել հետաքրքիր սցենարներ ավտոմատացման և որակի վերահսկման համար:

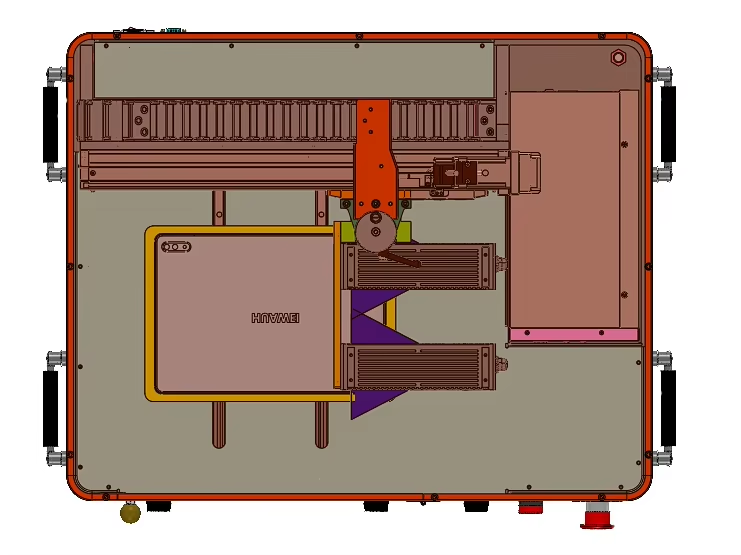

Որպես ազգային մակարդակով ճանաչված բարձր տեխնոլոգիական ձեռնարկություն՝ օժտված երկկի ծրագրային ապահովման և համակարգի ինտեգրման վկայականներով, մենք մասնագիտացած ենք մեքենայական տեսողության ծրագրային ապահովման, ռոբոտների, ճշգրիտ շարժման վերահսկման և ինտելեկտուալ ստուգման համակարգերի հիմնարար տեխնոլոգիաներում:

Նորարարական էներգետիկայի մատակարարման ստուգման տեխնոլոգիաների նախաձեռնող՝ մենք մեր առաջադեմ տեսողական համակարգերն ու արհեստական ինտելեկտի վրա հիմնված լուծումները կիրառում ենք արդյունաբերական արտադրության, ճշգրիտ մասերի և ինտելեկտուալ ավտոմատացման ոլորտներում՝ նպաստելով արագ աճող ոլորտներում նորարարությունների մշակմանը:

Մենք պահպանում ենք 100% արտադրանքի ստուգման մակարդակ՝ իրականացնելով խիստ որակի վերահսկողություն հումքի ձեռքբերումից և հավաքակցումից մինչև վերջնական փորձարկում և փաթեթավորում՝ ապահովելով հուսալիություն, համապատասխանություն և արդյունավետ մատակարարում գլոբալ հաճախորդներին:

Որակյալ ինժեներական թիմի աջակցությամբ մենք առաջարկում ենք տեսողական արտադրանքների հատուկ մշակում, արժեքով օպտիմալացված մատակարարում, կոնսոլիդացիայի ծառայություններ և հատուկ տրանսպորտային ծառայություններ՝ ապահովելով ամբողջական, արժեքով հարմար տեսողական լուծումներ և արագ սպասարկման աջակցություն: