The Jakange’s Aoi Logo Visual Inspection Machine is a cutting-edge piece of equipment designed to ensure the quality and accuracy of logos on various products. This optical inspection machine uses advanced technology to automatically detect any flaws or inconsistencies in the logos, ensuring that only perfect products make it to the market.

With the Jakange’s Aoi Logo Visual Inspection Machine, manufacturers can streamline their production processes and eliminate the need for manual inspection, saving time and resources. This machine is incredibly efficient, capable of inspecting hundreds of logos in a matter of minutes with unparalleled accuracy.

The Jakange’s Aoi Logo Visual Inspection Machine is incredibly user-friendly, with a simple and intuitive interface that allows operators to easily set up and monitor the inspection process. The machine is also highly versatile, able to handle logos of different sizes, shapes, and colors, making it suitable for a wide range of industries.

One of the key features of the Jakange’s Aoi Logo Visual Inspection Machine is its high-speed imaging system, which captures detailed images of each logo for in-depth analysis. The machine's powerful algorithms then compare these images to a reference image, identifying any discrepancies and flagging them for further inspection.

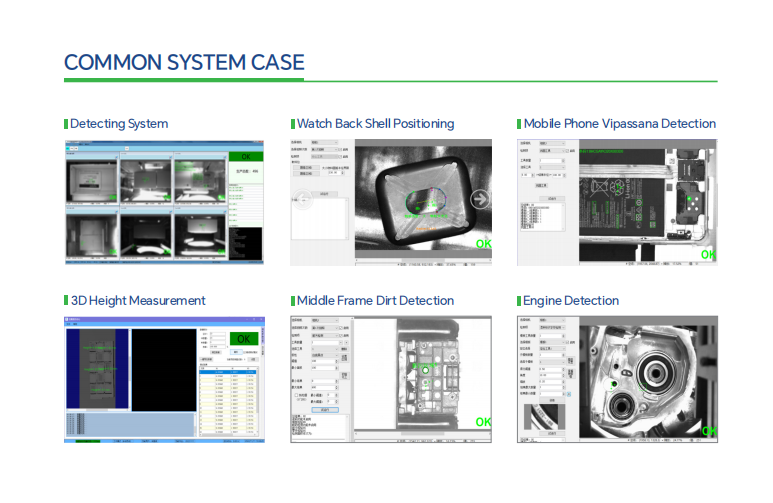

In addition to its logo inspection capabilities, the Jakange’s Aoi Logo Visual Inspection Machine can also be used to inspect other types of visuals, such as text, numbers, and graphics. This versatility makes it a valuable tool for manufacturers looking to ensure the overall quality of their products.

The Jakange’s Aoi Logo Visual Inspection Machine is a must-have for any manufacturer looking to enhance the quality control process and deliver flawless products to their customers. With its advanced technology, user-friendly interface, and versatile capabilities, this machine is sure to streamline production processes and improve overall efficiency. Trust in Jakange for all your visual inspection needs

Height of the operating |

750mm |

Equipment General Data |

5-7 inch phone |

Waste discharge mode |

Suction and place on NG belt |

Equipment Size - mm |

1200 x 750 x 1400 |

Network |

Upload MES |

Main function |

Mix and print icon detection Fouling detection Lens leakage detection Lens misalignment detection Key mis-installation, missing installation detection Cato missed loading and mixing test Middle frame color mix detection MES upload |