ໃນສະພາບການທີ່ມີການສະສົມສິນຄ້າໄວ້ໃນສາງຫຼາຍຢ່າງທີ່ເກີດຂຶ້ນໃນຂະແໜງການຜະລິດໃນປັດຈຸບັນນີ້ ເຕັກໂນໂລຊີກໍາລັງກ້າວໄປຢ່າງໄວວາກ່ອນໜ້າໃຜ. ຕົວຢ່າງໜຶ່ງຂອງການປະດິດສ້າງນະວະນຳພາໃນການກະຈາຍຕະຫຼາດໃນຂະແໜງການກວດກາແຜ່ນວົງຈອນ (PCB) ກໍຄືເຄື່ອງ 3D AOI. ລະບົບດັ່ງກ່າວນຳໃຊ້ເຕັກໂນໂລຊີລຸ້ນໃໝ່ສຸດ ແລະ ສະນັ້ນຈຶ່ງຮັບປະກັນວ່າແຜ່ນວົງຈອນບໍ່ມີຂໍ້ຜິດພາດ ແລະ ຄວາມຜິດພາດ ຈຶ່ງເຮັດໃຫ້ຄຸນນະພາບ ແລະ ຄວາມສາມາດໃນການເຊື່ອຖືໄດ້ຂອງຜະລິດຕະພັນດີຂຶ້ນ.

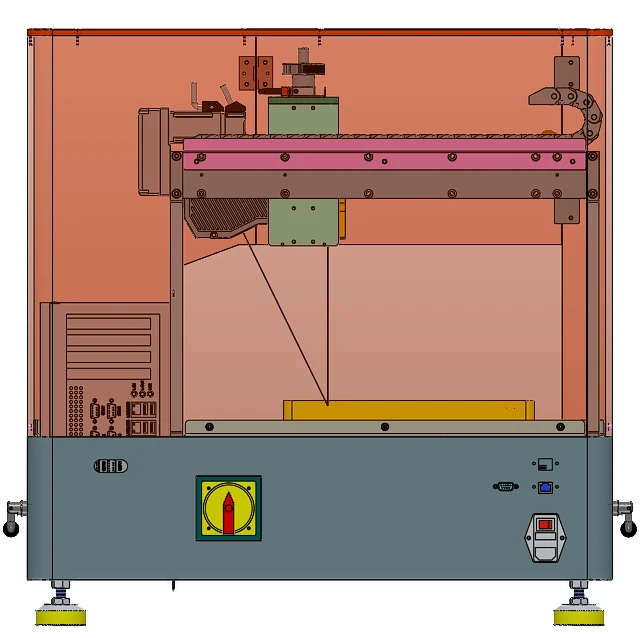

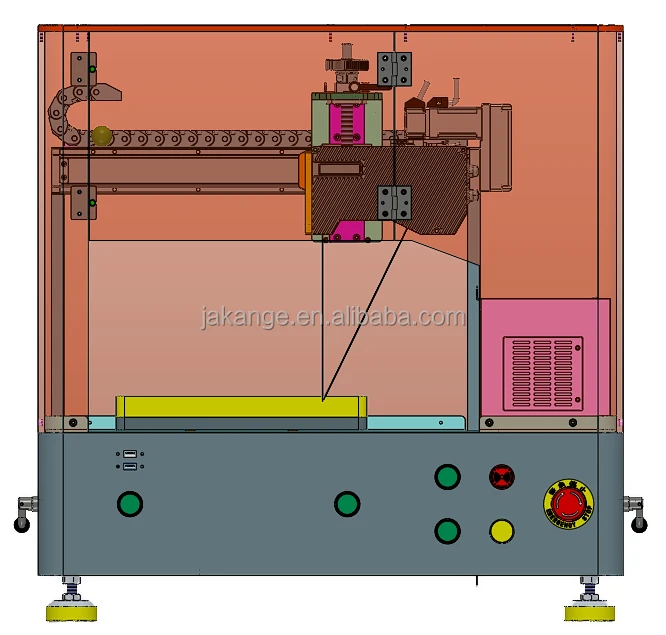

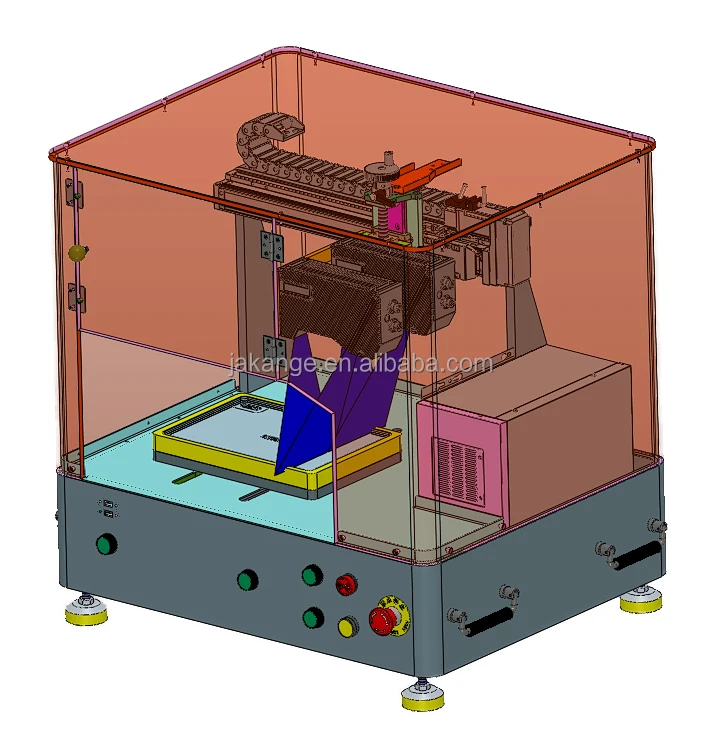

ພ້ອມກັບການພັດທະນາດ້ານເຕັກໂນໂລຊີ ຄວາມຕ້ອງການໃນການກວດກາແຜ່ນວົງຈອນ PCB ຢ່າງມີປະສິດທິພາບ ແລະ ຄວາມແນ່ນອນກໍເພີ່ມຂຶ້ນ. ວິທີການກວດກາແບບ 2D ທີ່ຜ່ານມານັ້ນບໍ່ສາມາດຕອບສະໜອງມາດຕະຖານດ້ານຄຸນນະພາບຂອງຂະແໜງການຜະລິດໃນປັດຈຸບັນໄດ້ອີກຕໍ່ໄປ. ແລະ ນີ້ແມ່ນບ່ອນທີ່ເຄື່ອງ 3D AOI ຖືກນຳໃຊ້. ເຄື່ອງຈັກເຫຼົ່ານີ້ຕິດຕັ້ງດ້ວຍເຊັນເຊີ ແລະ ອາລິກະຣິດທີ່ທັນສະໄໝ ເຊິ່ງສາມາດສ້າງມຸມມອງແບບ 3D ຂອງແຕ່ລະແຜ່ນວົງຈອນ PCB ໄດ້ ເຮັດໃຫ້ຂະບວນການກວດກາລະອຽດຫຼາຍຂຶ້ນ ແລະ ຖືກຕ້ອງຫຼາຍຂຶ້ນ.

ໜຶ່ງໃນຂໍ້ດີທີ່ສໍາຄັນທີ່ສຸດຂອງລະບົບ 3D AOI ແມ່ນການຊອກຫາຂໍ້ບົກຜ່ອງທີ່ວິທີການກວດສອບອື່ນໆອາດບໍ່ສາມາດຊອກພົບໄດ້. ເຄື່ອງຈັກດັ່ງກ່າວສາມາດກວດພົບບັນຫາເຊັ່ນ ຄວາມຜິດພາດໃນການບັດເຊື່ອມ, ຂໍ້ຜິດພາດໃນການຕຳໜ່າງຂອງອົງປະກອບ, ຄວາມເສຍຫາຍໃດໜຶ່ງໃນແຜ່ນວົງຈອນ (PCB), ແລະ ອື່ນໆ ໄດ້ຢ່າງແທ້ຈິງ. ການຊອກພົບຂໍ້ຜິດພາດໃນຂັ້ນຕອນຕົ້ນຈະຊ່ວຍປະຢັດເວລາ ແລະ ຄ່າໃຊ້ຈ່າຍໃຫ້ແກ່ຜູ້ຜະລິດໂດຍການປ້ອງກັນການເຮັດວຽກຄືນໃໝ່ ແລະ ການເອີ້ນຄືນຜະລິດຕະພັນທີ່ມີຄ່າໃຊ້ຈ່າຍສູງ.

ອົງປະກອບຂອງເຄື່ອງ 3D AOI ກໍາລັງປ່ຽນວິທີການດໍາເນີນທຸລະກິດໂດຍເຮັດໃຫ້ຂະບວນການກວດສອບເປັນໄປຢ່າງໄວວາກວ່າ ແລະ ມີປະສິດທິພາບຫຼາຍຂຶ້ນ. ເຄື່ອງຈັກດັ່ງກ່າວສາມາດກວດສອບແຜ່ນວົງຈອນ (PCB) ໄດ້ໄວກ່ວາການກວດສອບດ້ວຍມືຢ່າງຫຼວງຫຼາຍ, ສະນັ້ນຈຶ່ງເຮັດໃຫ້ຜູ້ຜະລິດສາມາດປະຕິບັດຕາມແຜນການຜະລິດທີ່ເຂັ້ມງວດໄດ້ຢ່າງສະດວກສະບາຍຫຼາຍຂຶ້ນ. ນອກຈາກນັ້ນ, ລະດັບຄວາມແທ້ຈິງສູງທີ່ເຄື່ອງ 3D AOI ຮັບປະກັນໄດ້ ຈະເຮັດໃຫ້ແຜ່ນວົງຈອນ (PCB) ທີ່ສົມບູນເທົ່ານັ້ນຈຶ່ງຈະຖືກຜ່ານໄປສູ່ຂັ້ນຕອນຕໍ່ໄປ, ຊຶ່ງຊ່ວຍປະຢັດເວລາ ແລະ ບັນດາຊັບພະຍາກອນໃນໄລຍະຍາວ.

ຄວາມຜິດພາດໃນການຜະລິດ PCB ສາມາດສົ່ງຜົນກະທົບຢ່າງຮ້າຍແຮງ ຈາກການທີ່ສິນຄ້າໃຊ້ງານບໍ່ໄດ້, ພົງເສຍ ຫຼື ບໍ່ປອດໄພ. ເຄື່ອງ 3D AOI ມີບົດບາດສຳຄັນໃນການປ້ອງກັນຂໍ້ຜິດພາດເຫຼົ່ານີ້ບໍ່ໃຫ້ເຂົ້າສູ່ຜະລິດຕະພັນສຳເລັດຮູບ ໂດຍການກວດສອບ PCB ສຳລັບຂໍ້ບົກຜ່ອນກ່ອນທີ່ພວກມັນຈະຖືກປະກອບເຂົ້າໃນຜະລິດຕະພັນສຳເລັດ. ສຳລັບຜູ້ຜະລິດ, ການຈັບຂໍ້ຜິດພາດໃນຂັ້ນຕອນຕົ້ນ ພວກເຂົາສາມາດຮັບປະກັນຄຸນນະພາບ ແລະ ສ້າງຊື່ເສียงດ້ານຄຸນນະພາບທີ່ພວກເຂົາຈະພູມໃຈໃນການແບ່ງປັນ.

ເຄື່ອງ 3D AOI ແທ້ຈິງມີບົດບາດສຳຄັນຫຼາຍໃນການຮັບປະກັນຄຸນນະພາບ ແລະ ຄວາມສາມາດໃນການໃຊ້ງານຂອງຜະລິດຕະພັນໂດຍລວມ. ສຳລັບຜູ້ຜະລິດ, ການຜະລິດ PCB ທີ່ບໍ່ມີຂໍ້ບົກຜ່ອນແມ່ນສິ່ງສຳຄັນໃນການສົ່ງຜະລິດຕະພັນທີ່ມີຄຸນນະພາບສູງອອກສູ່ຕະຫຼາດ ທີ່ເຊີນຕອບສະໜອງ ຫຼື ເກີນຄາດໝາຍຂອງລູກຄ້າ. ສິ່ງນີ້ຈະຊ່ວຍເພີ່ມຄວາມພໍໃຈຂອງລູກຄ້າ ແລະ ຄວາມສະຫງົບໃຈຕໍ່ຍີ່ຫໍ້ ແລະ ສຸດທ້າຍກໍຈະນຳໄປສູ່ການຂະຫຍາຍໂຕຂອງທຸລະກິດສຳລັບບໍລິສັດເຊັ່ນ Jakange.

ເປັນຜູ້ນຳໜ້າໃນດ້ານເຕັກໂນໂລຢີການກວດກາຖ່ານໄຟພະລັງງານໃໝ່, ພວກເຮົານຳໃຊ້ລະບົບມຸມມອງຂັ້ນສູງ ແລະ ວິທີການທີ່ຂັບເຄື່ອນດ້ວຍ AI ຂອງພວກເຮົາໃນຂະແໜງການຜະລິດອຸດສາຫະກຳ, ສ່ວນປະກອບຄວາມແນ່ນອນ, ແລະ ອັດຕະໂນມັດອັດສະລິຍະພາບ, ເພື່ອຂັບເຄື່ອນການປະດິດສ້າງໃນຂະແໜງການທີ່ກຳລັງເຕີບໂຕສູງ.

ພວກເຮົາຮັກສາອັດຕາການກວດກາຜະລິດຕະພັນ 100%, ດຳເນີນການຄວບຄຸມຄຸນນະພາບຢ່າງເຂັ້ມງວດ ຈາກການຊື້ວັດຖຸດິບ, ການປະສົມປະສານ, ການທົດສອບສຸດທ້າຍ ແລະ ການຫຸ້ມຫໍ່—ເພື່ອຮັບປະກັນຄວາມໜ້າເຊື່ອຖື, ການປະຕິບັດຕາມ, ແລະ ການຈັດສົ່ງທີ່ມີປະສິດທິພາບໃຫ້ແກ່ລູກຄ້າທົ່ວໂລກ.

ໃນຖານະທີ່ເປັນວິສາຫະກິດເຕັກໂນໂລຢີສູງທີ່ໄດ້ຮັບການຮັບຮອງໃນຂັ້ນແຫ່ງຊາດ ແລະ ມີໃບຢັ້ງຢືນດ້ານຊອບແວ ແລະ ລະບົບບູລະນະການສອງຢ່າງ, ພວກເຮົາຊ່ຽວຊານດ້ານເຕັກໂນໂລຢີຫຼັກ ເຊັ່ນ: ຊອບແວມຸມມອງຈັກ, ຫຸ່ນຍົນ, ການຄວບຄຸມການເຄື່ອນໄຫວແບບແນ່ນອນ, ແລະ ລະບົບການກວດກາອັດສະລິຍະພາບ.

ດ້ວຍການຮັບຮອງຈາກທີມງານວິສະວະກອນທີ່ມີຄວາມຊໍານິຊໍານານ, ພວກເຮົາຂໍສະເໜີການພັດທະນາຜະລິດຕະພັນດ້ານເທັກນິກການມອງເຫັນຕາມຄວາມຕ້ອງການ, ການຈັດຊື້ທີ່ປັບປຸງຕົ້ນທຶນໃຫ້ດີຂຶ້ນ, ການບໍລິການລວມສູນ, ແລະ ການຂົນສົ່ງພິເສດ—ໂດຍສະເໜີວິທີແກ້ໄຂດ້ານເທັກນິກການມອງເຫັນທີ່ຄົບຖ້ວນ, ມີປະສິດທິພາບດ້ານຕົ້ນທຶນ, ແລະ ການສະໜັບສະໜູນຫຼັງການຂາຍທີ່ທັນໃຊ້