Introducing, the Jakange’s High-Performance Smart AI Edge Computing Industrial Computer Machine Vision Inspection Deep Learning system for overhead accessories. This cutting-edge technology is designed to revolutionize the way industrial inspections are conducted, providing unmatched accuracy and efficiency.

The Jakange system utilizes state-of-the-art AI algorithms to analyze images and data collected from overhead accessories, identifying potential issues and defects with incredible speed and precision. By harnessing the power of deep learning technology, this system can quickly adapt and learn from new data, continuously improving its performance over time.

With its high-performance smart AI edge computing capabilities, the Jakange system is able to process vast amounts of data in real-time, providing instant feedback to operators and minimizing downtime. This ensures that any issues with overhead accessories can be addressed promptly, preventing costly disruptions to the production process.

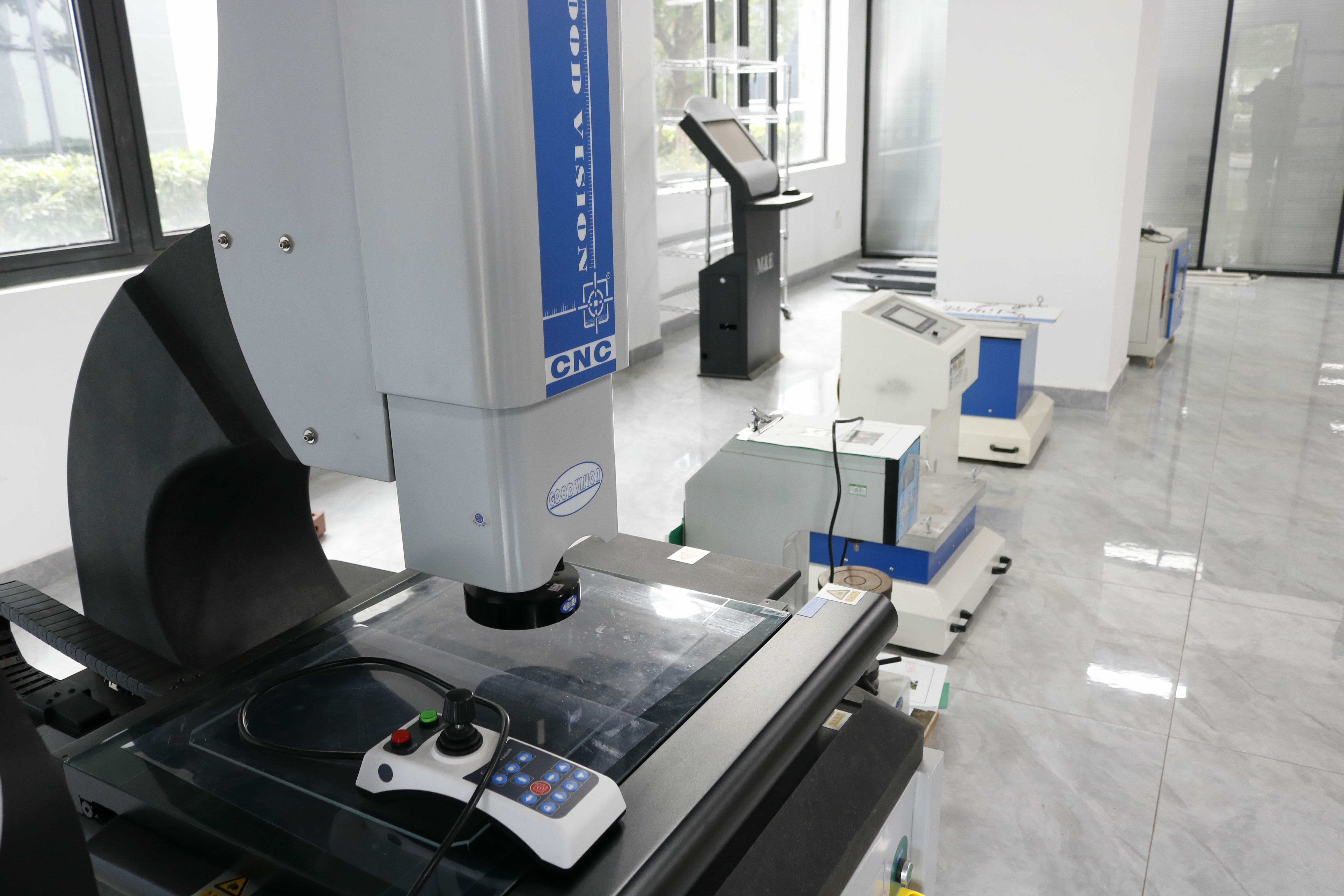

The industrial computer at the heart of the Jakange system is specifically designed to withstand harsh industrial environments, making it ideal for use in manufacturing facilities and warehouses. Its rugged construction and reliable performance ensure that it can operate efficiently in even the most demanding conditions.

Thanks to its machine vision inspection technology, the Jakange system is able to capture high-quality images of overhead accessories, allowing for detailed analysis and accurate defect detection. This makes it an invaluable tool for quality control and maintenance purposes, helping to ensure that all components meet the highest standards of safety and reliability.

The Jakange’s High-Performance Smart AI Edge Computing Industrial Computer Machine Vision Inspection Deep Learning system is a game-changer in the field of industrial inspections for overhead accessories. Its advanced technology, reliable performance, and unmatched accuracy make it the ideal solution for companies looking to optimize their production processes and maximize efficiency. Invest in the Jakange system today and take your business to the next level

White/Black 3U custom chassis |

Yes |

Main board |

ATX Intel H110 |

Power Consumption |

350 |

Processor CPU |

I3 - 6100 CPU |

Internal memory |

4GB |

Hard disk |

1tb |

Light source control |

Optional - 4 digital light source brightening module, support visual light source brightness control, maximum power support 120W |

I O |

Optional - 8-channel isolated IO control |

String communication interface |

4 RS232 - 2 of which can be set to RS422/485 |

Display interface |

VGA / DVI / HDMI / DP |

Ethernet interface |

Three Gigabit Ethernet interfaces |

Enviroment |

||

Operating Temperature |

0~40 °C - 32~104 °F |

|

Non-Operational Temperature |

-20~60 °C -4~140 °F |

|

Operating Humidity |

10 ~ 85% @ 40° C, non-condensing |

|

Non-Operating Humidity |

0 ~ 95% @ 60° C, non-condensing |

|

|

Operating temperature: -10~50° C Storage temperature: -20~60° C Humidity: 5~ 90% - no condensation |

||

1. Any inquiries will be replied within 24 hours

2. Professional manufacturer.

3. OEM/ODM available: Please let us know your details, then we can help you to design and put it into production.

4) Technology support at any time.

One week delivery for small orders, and 2~4 weeks for large order(above 50pcs).

You can pay for the order via:T/T.