స్మ న్ ట ్ అసెంబ్లీ సామర్థ్యాన్ని, వేగాన్ని మెరుగుపరచడం

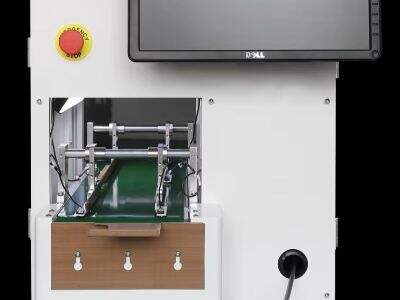

ఒక పజిల్ ను కలపడానికి ప్రయత్నిస్తున్నట్లు ఊహించుకోండి, ప్రతి ముక్క ఎక్కడ సరిపోతుందో గుర్తించడానికి మీ కళ్ళను ఉపయోగించడానికి బదులుగా, మీకు ఒక ప్రత్యేక యంత్రం ఉంది, అది సరైన మ్యాచ్ ను సెకనులో కనుగొనగలదు. అందుకే మీరు ఒక ఆప్టికల్ ఇన్స్పెక్షన్ సిస్టమ్ SMT అసెంబ్లీలో యంత్రం! వేలాది చిన్న భాగాలు సరైన స్థానంలో ఉన్నాయని నిర్ధారించడానికి ప్రతి సర్క్యూట్ బోర్డును వేగంగా స్కాన్ చేయడం ద్వారా ఇది జాకాంజ్ కార్మికులకు సహాయపడుతుంది. ఇది చాలా సమయాన్ని ఆదా చేస్తుంది, మరియు మీరు ప్రతిదీ కలిసి కలిగి నిర్ధారించడానికి.

నాణ్యత నియంత్రణ మరియు లోపం గుర్తించడం సమయం స్థిరంగా పద్ధతిలో

నాణ్యత నియంత్రణ అనేది ఒక డిటెక్టివ్ లాంటిది, అసెంబ్లీ ప్రక్రియలో తమ మార్గాన్ని కనుగొన్న ఏ లోపాలు లేదా లోపాల కోసం వెతుకుతుంది. వారి వద్ద ఒక AOI యంత్రం తో, జాకాంజ్ వారి సర్క్యూట్ బోర్డులు అన్ని నిశితంగా తనిఖీ చేయబడుతున్నాయి తెలుసుకోవడం, విశ్రాంతి నిద్ర చేయవచ్చు. ఈ యంత్రం చాలా తెలివైనది, మానవ కంటికి కనిపించని సూక్ష్మ లోపాలను చూడగలదు, మరియు వాటిని ప్రారంభంలో గుర్తించడం ద్వారా, జాకాంజ్ వారి ఉత్పత్తులు సాంకేతికంగా అగ్రశ్రేణిగా ఉన్నాయని మరియు ప్రపంచానికి వెళ్ళడానికి సిద్ధంగా ఉన్నాయని నిర్ధారించుకోవచ్చు.మానవ లోపాల తొలగింపు మరియు ఉత్పత్తి వ్యయ ఆదా

మీరు ఎప్పుడైనా ఒక ఆట ఆడుతున్నప్పుడు లేదా హోంవర్క్ చేస్తున్నప్పుడు చెత్తగా? ఇది మనందరికీ జరుగుతుంది! కానీ ఎలక్ట్రానిక్ పరికరాల తయారీలో ఒక చిన్న తప్పు చాలా ఖరీదైనది కావచ్చు. అందుకే ఒక యంత్రం పారిశ్రామిక దృష్టి యంత్రం Jakange కోసం చాలా కీలకం. ఈ యంత్రం ఒక వ్యక్తి స్థానంలో పనిచేస్తుంది లోపం తనిఖీ పని చేయడం ద్వారా, అది తక్కువ తప్పులు జరిగే అవకాశం చేస్తుంది. మరియు అదనపు బోనస్ గా, ఇది కూడా మీరు డబ్బు ఆదా, మొదటిసారి సరిగ్గా ప్రతిదీ జరుగుతుంది నిర్ధారించుకోండి ద్వారా.

ప్రక్రియను సరళీకృతం చేయడం మరియు ఉత్పాదకతను మెరుగుపరచడం

మీరు ఒంటరిగా పరుగులు చేయవలసిన అవసరం లేదు; మీరు సూపర్-ఫాస్ట్ రోబోట్ల బృందాన్ని మీతో నడుపుతారు. ఇది జాకాంగే యొక్క SMT అసెంబ్లీ లైన్ కోసం ఒక AOI యంత్రం ఏమిటి! ఈ యంత్రం వేగంగా, సమర్థవంతంగా పనిచేస్తుంది. అంటే జకాంజ్ తక్కువ సమయంలో ఎక్కువ ఉత్పత్తులను ఉత్పత్తి చేయగలదు, మరియు ఇది వారి అద్భుతమైన గాడ్జెట్ల డిమాండ్తో పాటుగా ఉండటానికి సహాయపడుతుంది.

పోటీదారుల కంటే ముందుగా ఉండడం మరియు పరిశ్రమ అవసరాలను తీర్చడం

వస్తువుల తయారీలో, అనేక ఇతర దుస్తులు తమకు సాధ్యమైనంత ఉత్తమమైన ఉత్పత్తులను తయారు చేయడానికి ప్రయత్నిస్తాయి. జాకాంగే శబ్దం పైన ఎదగడానికి, వారు కొన టాప్ ఆకారం ఉండాలి. వారు ఒక దృశ్య పరిశీలన యంత్రాలు తమ ఉత్పత్తి ఉత్తమమైనదేనని, ఉత్తమమైన వాటితో పోటీ పడగలదని నిర్ధారించుకోవడానికి యంత్రం. ఈ ఉపకరణం ద్వారా జాకాంజ్ పరిశ్రమ ప్రమాణాలను పాటించగలుగుతుంది మరియు వారు తీవ్రమైన సంస్థ అని ప్రపంచానికి తెలియజేస్తుంది.

ప్రపంచంలోనే అత్యంత అధునాతనమైన SMT లైన్ ను కలిగి ఉంటే, జకాంగేలో మాదిరిగానే ఆటోమేటిక్ ఆప్టికల్ ఇన్స్పెక్షన్ మెషీన్తో అమర్చబడితే ఎంత ప్రయోజనకరంగా ఉంటుందో. అధిక సామర్థ్యం, అధిక ఖచ్చితత్వం, నాణ్యత నియంత్రణ, లోపం గుర్తించడం, మానవ లోపం మరియు ఉత్పత్తి వ్యయం తగ్గింపు, వేగవంతమైన టర్న్-ఆన్, అధిక ఉత్పాదకత, పరిశ్రమలో పోటీని అధిగమించడం మరియు అవసరాలను తీర్చడం, ఈ యంత్రం మంచి నాణ్యమైన ఉత్పత్తిని ఉత్పత్తి చేయాలనుకునే సంస్థకు ని వారి నమ్మకమైన AOI యంత్రం దాని పనిని చేస్తున్నందున, జకాంజ్ వారి అద్భుతమైన గాడ్జెట్లతో రాబోయే సంవత్సరాల్లో ప్రపంచాన్ని ఆకట్టుకోగలదు!