Special types of technology like industrial vision systems assist factories, and manufacturers in general, in making products both better and faster. Jakange vision systems are eyes that can see that which we cannot. These systems enable machines to confirm mistakes, measure things accurately and even make decisions on their own. Let’s discuss how industrial vision systems are able to boost productivity, quality control, and production processes at factories.

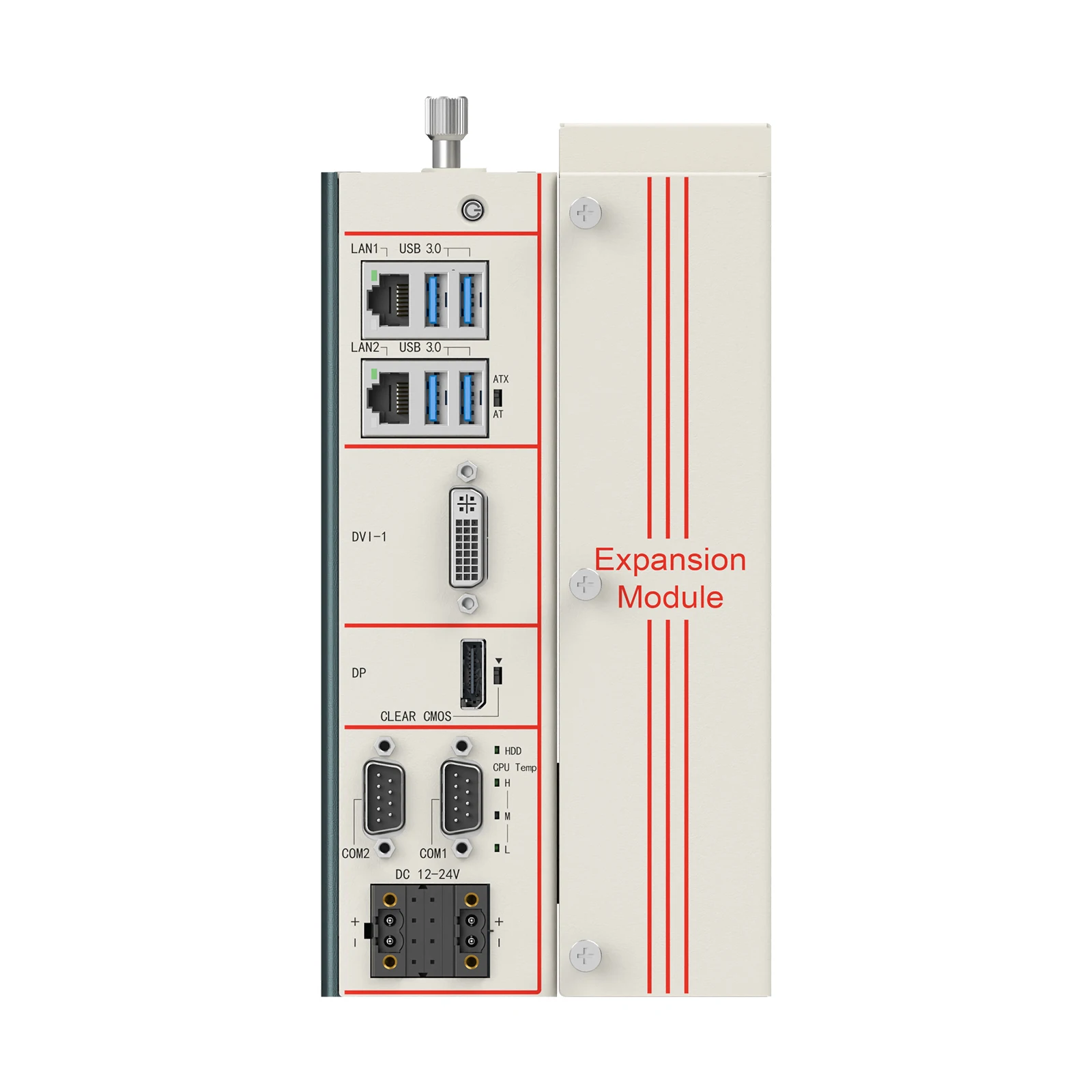

Productivity is the act of making things — well, takes time and energy. Factories can benefit from vision systems like these. These systems, which work in tandem with cameras and specialized software, are designed to help machines perform faster and more accurately. For instance, they will assist robots to grab an object and place it at the right location without errors. That is, factories can produce more within the same time frame, generate more money.

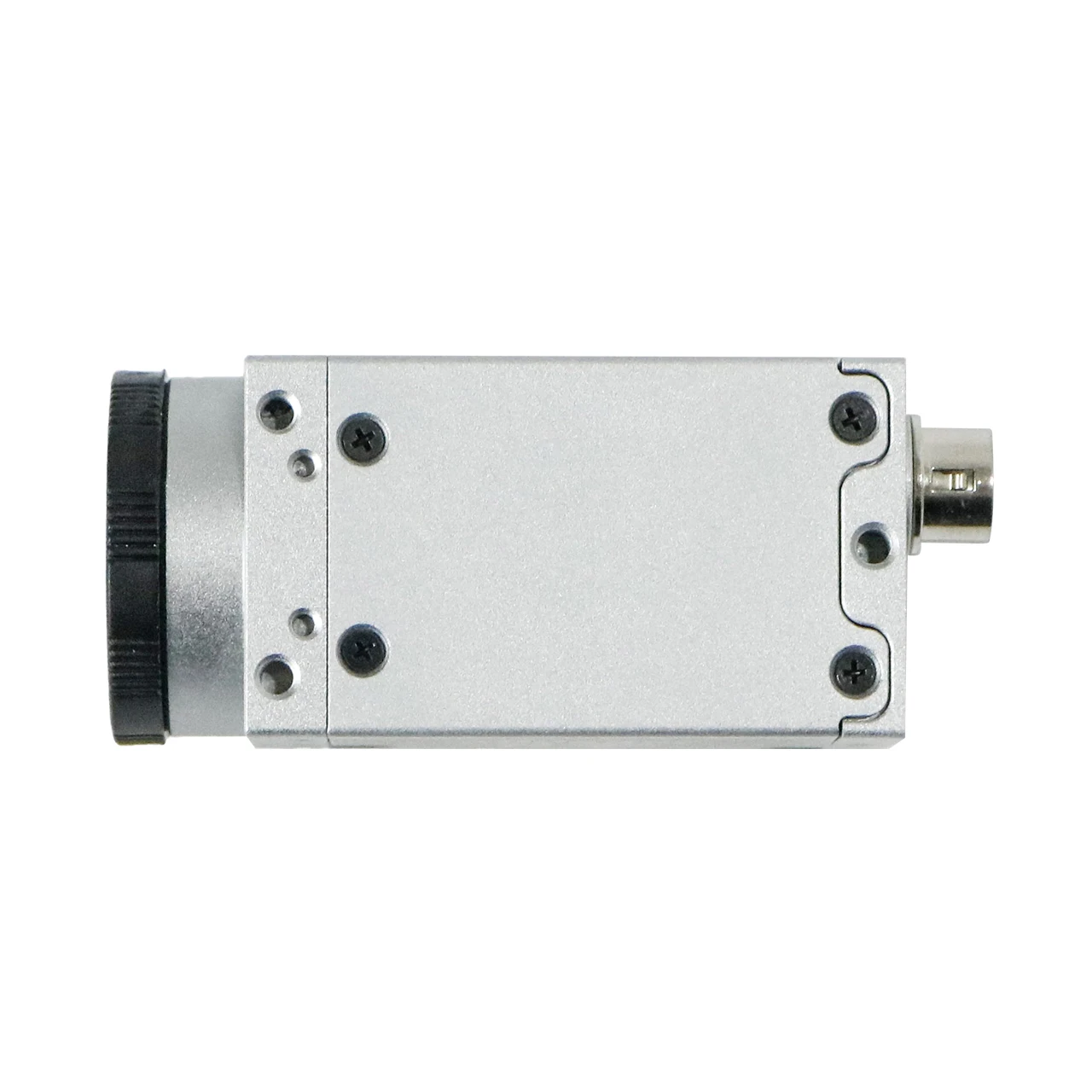

Quality control is a concern, because it is necessary for products to be built the way they’re supposed to be built. Factory vision systems can assist in the inspection of products for problems. For instance, they might search for scratches, dents or other problems that can occur while making those products. By discovering these issues early, factories can repair them before shipping the goods to customers. Jakange machine vision camera serves to increase customer satisfaction.

There are so many steps in the production process, from raw materials to finished product. Factories can be assisted in these productions by industrial vision technology that makes some of these steps easier by automating part of them. For instance, cameras can monitor machines in real time, identifying any issues before they escalate. This allows factories to save time and money that a breakdown or production delay would cost. And Jakange industrial machine vision can be used to improve workflows by identifying slow parts and production line problems.

Industrial vision systems are revolutionizing how products are created. By way of cameras, sensors and artificial intelligence, these systems help factories work smarter and faster. Jakange vision inspection system can be used, for instance, to allow machines to talk to one another and to make rapid decisions. This allows factories to respond to changes in their production needs and to make their processes operate better. Industrial vision systems are becoming widespread in production, helping to make our manufacturing processes more efficient, accurate and competitive.

Supported by a skilled engineering team, we offer tailored vision product development, cost-optimized sourcing, consolidation services, and specialized logistics—providing complete, cost-effective visual solutions and responsive after-sales support.

A pioneer in new energy battery inspection technology, we apply our advanced vision systems and AI-driven solutions across industrial manufacturing, precision components, and smart automation, driving innovation in high-growth sectors.

As a nationally recognized high-tech enterprise with dual software and system integration certifications, we specialize in core technologies including machine vision software, robotics, precision motion control, and intelligent inspection systems.

We maintain 100% product inspection rates, implementing strict quality oversight from raw material sourcing and assembly to final testing and packaging—ensuring reliability, compliance, and efficient delivery for global clients.